The basic type of this articulated luminaire dates back to the electrification phase in the early 20th century and aimed at a wide-ranging, steerable and precisely adjustable workplace luminaire. Famous representatives were the lamps of Auma, RIMSA, Luxo L-1, Anglepoise and Jielde. The design, towering, with predetermined bends and heavy head, makes considerable demands on technical finesse.

RIMSA models are characterized by the patented steel articulated socket at the end of the arm, which is still manufactured with the original shape from 1946. Thanks to it, the lamp head can be swiveled generously. The light cone can be easily and steplessly adjusted to almost any angle to illuminate the desired spot with centimeter precision.

We carry two proven RIMSA spring-loaded luminaires in different versions, the Model 10 and the Model 80. We have also included the RIMSA Mec 103 work light, which has a coupling mechanism instead of the spring-loaded mechanism; the high quality of the design is identical.

The available models from Rimsa

The Model 80 from RIMSA compared with a low-price model.

Since the 1980s, the caricature of such a workstation lamp has been pushed onto the market at rock-bottom prices, resulting among other things from the adventurous assumption that, if need be, the simple connection of screw and nut could also be considered a joint. For some years now, there have been attempts to make up for this then completely screwed-up design. In Hamburg, the Auma lamp is being rebuilt as “Midgard”, with care, but at extremely high prices. We bring the Italian original type from the 1930s, manufactured today as then by RIMSA of Seregno, Italy, a manufacturer that has established itself in the market for special medical lights, but is rebuilding for us the originals of its articulated lights from the 1946 and 1964 model years. On the right you see here the RIMSA, on the left the low-price model. The difference is visible and tangible.

In particular, the difference in size between the two lights is immediately apparent. The luminaire arm of the sheet steel RIMSA model is a full 30 cm longer. The RIMSA lower arm has three struts instead of two. The RIMSA struts are also more powerfully designed, the springs are stronger, longer and wider, and the shade is not only larger but also better proportioned. It has a flanged reflector, which our comparison model lacks.

The Model 80 from RIMSA compared with a low-price model.

Since the 1980s, the caricature of such a workstation lamp has been pushed onto the market at rock-bottom prices, resulting among other things from the adventurous assumption that, if need be, the simple connection of screw and nut could also be considered a joint. For some years now, there have been attempts to make up for this then completely screwed-up design. In Hamburg, the Auma lamp is being rebuilt as “Midgard”, with care, but at extremely high prices. We bring the Italian original type from the 1930s, manufactured today as then by RIMSA of Seregno, Italy, a manufacturer that has established itself in the market for special medical lights, but is rebuilding for us the originals of its articulated lights from the 1946 and 1964 model years. On the right you see here the RIMSA, on the left the low-price model. The difference is visible and tangible.

In particular, the difference in size between the two lights is immediately apparent. The luminaire arm of the sheet steel RIMSA model is a full 30 cm longer. The RIMSA lower arm has three struts instead of two. The RIMSA struts are also more powerfully designed, the springs are stronger, longer and wider, and the shade is not only larger but also better proportioned. It has a flanged reflector, which our comparison model lacks.

Precise adjustment possibilities thanks to optimal springs.

The demands on the RIMSA are high, and the luminaire lives up to them: cleanly working joints that reliably hold a selected setting, but allow corrections at any time and balance the effects of gravity for a long time with spring balancers that do not fatigue or wear out. On the right the RIMSA, on the left the low-price model

Durability due to the choice of proper materials.

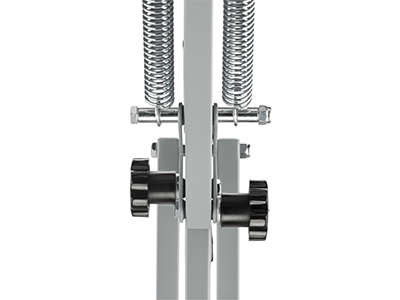

In the low-price model, the lamp head is not held by a joint socket, but by a clamped little arm, and only here can it be tightened with the help of a three-winged grip nut. At the “elbow,” where the screws on our comparison model can only be moved with the help of a wrench, the RIMSA light features two large, easy-to-grip handle screws whose impressively solid thread is made of brass. With the comparison light, you need a wrench to get it back into shape if necessary and create a condition that, from experience, does not last long.

Adaptable thanks to screws for resistance regulation.

You can change the position of the luminaire head at any time. Wherever you want to set the center of gravity of the light cone, the RIMSA stays where it should. With the screws you determine the mobility of the joints. On the left the RIMSA, on the right the low-price model.

The Rimsa in detail.

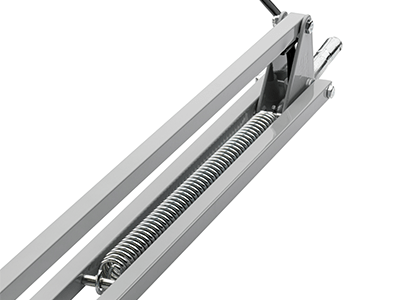

RIMSA, Model 80: The lower spring in detail.

RIMSA, Model 80: Bracing in detail.

RIMSA, Model 80: The joint in detail.

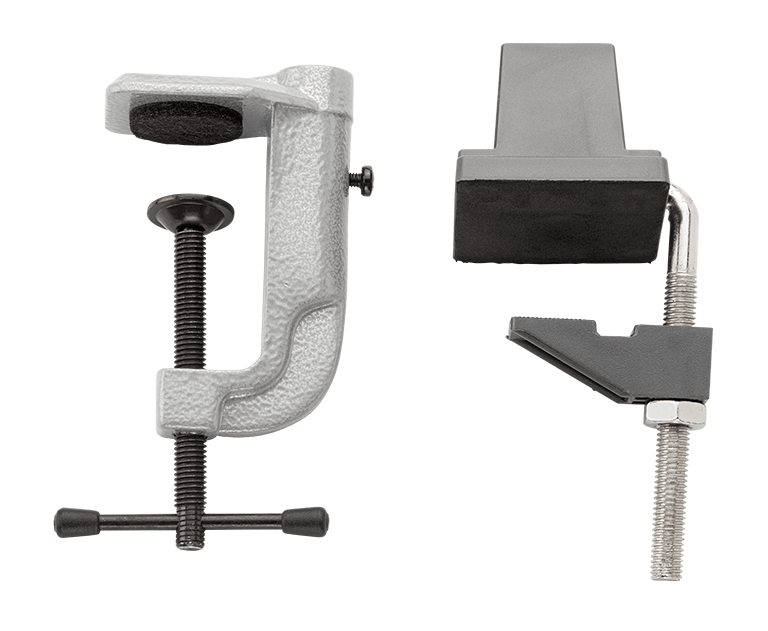

Luminaire feet

The RIMSA stands and holds without wobbling. There is a suitable foot for every application. Be it the massive stand, which weighs 10.4 kg with its cast iron core, be it the screw-on clamp base, the wall mounting bracket or the table mounting base.

The 130 g cast aluminum clamping base is made in one piece, unlike the comparison light (pictured right). In the latter, the clamping effect is achieved with the help of a separate plastic part, which naturally offers less stability.